|

Products List

|

|

Home > New Products > Germanium Lenses with Infrared Anti-reflection Coatings

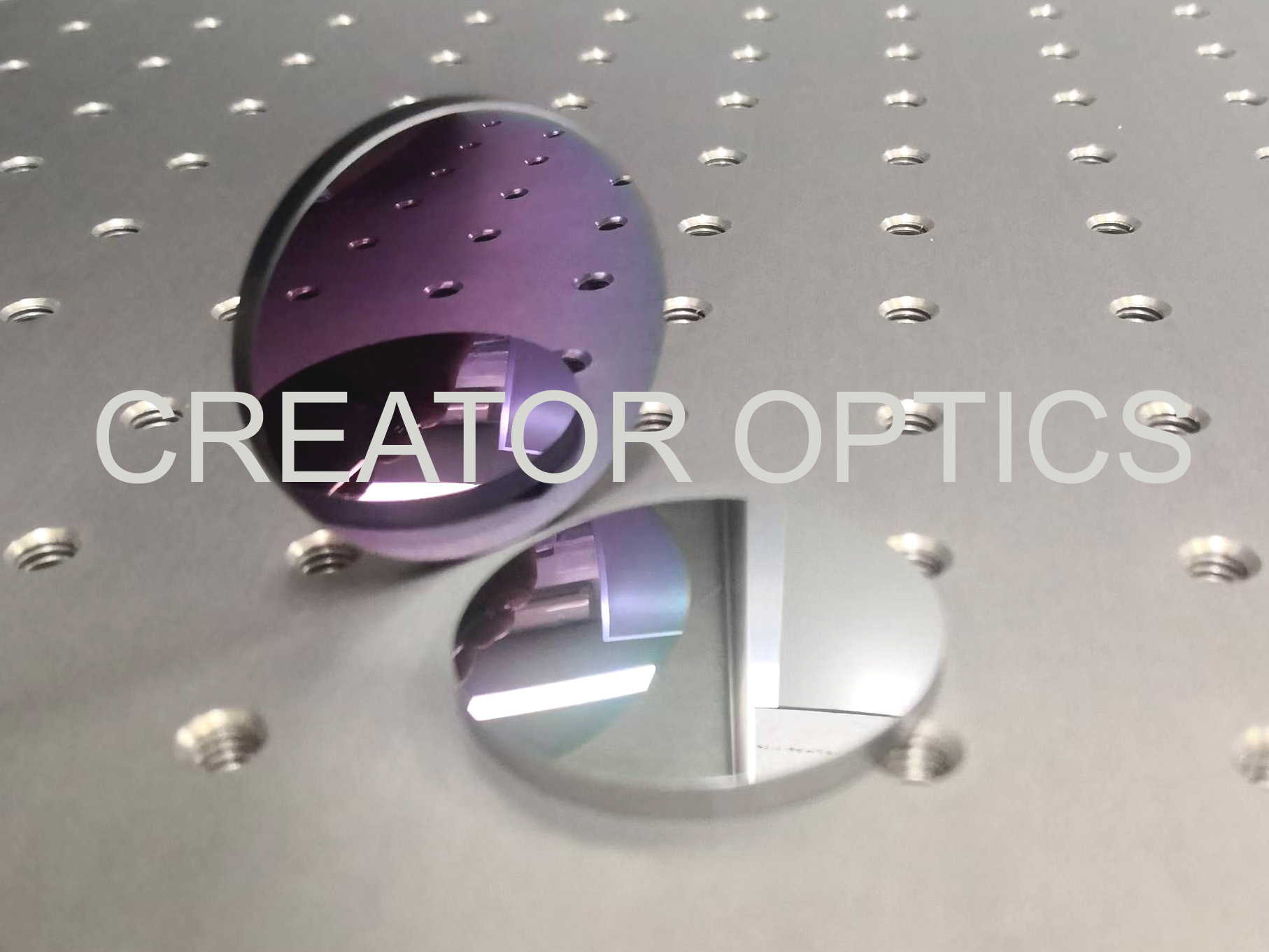

Germanium Lenses with Infrared Anti-reflection Coatings

|

- Infrared grade germanium single crystal, N-type, Pure

- The type is the same as that of conventional optical lenses (PCX/PCV/DCX/DCV/CXCV)

- Precise grinding size and surface quality

- Infrared-grade polishing as well as aspherical turning

- Precise surface accuracy

- Flash-free protective chamfer

- Optimized enhanced infrared optical anti-reflection coatings

- Available in case-hardening and diamond-like carbon coatings

- Reliable resistance to harsh environments (rain and fog, salt erosion, sand)

|

In infrared cameras and infrared lens assemblies, germanium lenses are widely used. Like other conventional optical lenses, germanium lenses can be designed to be the following types:

Plano-convex germanium lens (PCX)

Plano-concave germanium lens (PCV)

Biconvex germanium lens (PCV)

Biconcave germanium lens (PCV)

Convex-concave germanium lens (CXCV)

In addition, there are special aspheric germanium lenses. All of these lenses need to be designed and fabricated infrared anti-reflection coatings for specific applications to increase their overall transmittance in the infrared wavelength.

How to produce high quality infrared germanium lenses? Creator Optics selects high-purity infrared grade germanium single crystal as the lens substrates. These germanium crystal ingots are processed into the required precise external dimensional germanium lens blanks by CNC cutting machines, multi-wire cutting machines, round grinding machines, spherical milling machine and other equipment. Then, these germanium lens blanks are subjected to multi-step precision polishing to achieve the desired surface finish, surface accuracy, and various parameters. For aspherical germanium lenses, specific aspherical shapes need to be machined using precision diamond single point lathes.

How to make high-quality infrared anti-reflection coatings on these germanium lenses?

The infrared anti-reflection coating reduces the reflection on the surface of the germanium lens to increase the transmittance of the lens. Design and optimize infrared anti-reflection coatings based on the application of germanium lenses. These uncoated germanium lenses are then deeply cleaned and coated performed by PVD or CVD.

How to guarantee the performance of germanium lenses with infrared anti-reflection coatings

All germanium lenses with infrared anti-reflection coatings provided by Creator Optics are strictly quality inspected. Certified raw material suppliers, precise measurement of lens geometric dimensions, microscopic inspection of surface quality, spectral measurements as well as reliability testing and so on. All of these germanium lenses coated with infrared anti-reflection coatings have factory quality certification.

Specifications of Germanium Lenses with Infrared Anti-reflection coatings:

| Dimensions |

Diameter from 5mm to 150mm, customized available |

| |

S1 |

S2 |

| Dimensions Tolerance |

+/-0.1mm |

+/-0.1mm |

| Thickness Tolerance |

+/-0.1mm |

| Lens Edge |

fine ground |

fine ground |

| Chamfer/Bevel |

0.25x45 degrees (no-chips) |

0.25x45 degrees (no-chips) |

| Surface Accuracy |

1/10 lambda per inch @10.6um |

1/10 lambda per inch @10.6 um |

| Centrality |

30 arc seconds |

| Surface Qulitity |

40/20 |

40/20 |

| Clear Aperture |

>85% |

>85% |

| Coating |

AR/AR coating at 7-15 microns, AR+DLC @ 7-14um, customized available |

| Material |

Infrared grade germanium monocrystal (Ge) |

* Detailed characteristics of Germanium (Ge) monocrystal >>>

* Inquire about germanium lenses with infrared anti-reflection coatings or detailed of infrared optical coatings for germanium lenses, please contact our sales engineers.

|